Table of Contents

Chocolate’s been around forever—like, ancient civilizations were totally obsessed. But those old-school chocolate-making setups? Pretty basic. We’re talking stone grinding, lots of elbow grease, maybe some smoke and a mess. Then, humans being the tinkerers we are, started building all sorts of contraptions. Fast-forward a few centuries and boom: evolution of chocolate-making machines.

Seriously, the leap is wild. Those old techniques? They weren’t just for show. They’re the bones of today’s fancy gadgets—machines with more buttons than a spaceship, sensors everywhere, and, honestly, probably smarter than half the people in my group chat. You want precision? These things have it dialed in. Speed? Don’t blink. And the impact? Total game-changer for chocolatiers. Production’s way faster, quality’s up, and there’s enough variety to make your head spin.

Historical Overview

Way before fancy gadgets took over, chocolate wasn’t some easy grab-and-go snack. Nope. The OGs—those Mesoamerican folks—had to put in some serious elbow grease. Picture them hunched over, grinding cacao beans on stone slabs called metates (bet your wrists would hurt after five minutes). They’d toss in some spices, add water, and boom—this rich, frothy drink came out of it. Oh, and don’t even think regular people got a taste. This stuff was strictly VIP—nobles, priests, big shots only.

Fast forward: trade routes open up, and suddenly Europe’s obsessed. Everyone wants a piece, and bam, the quest for better, easier chocolate just snowballs from there. That’s when the chocolate game really starts to change.

- Traditional Methods

On a smaller scale, chocolate-making relied heavily on manual labor, where artisans used rudimentary techniques to roast, grind, and conch cacao beans. These traditional methods ensured the preservation of flavor, while also allowing artisans to experiment with various ingredients and recipes, fostering a deep appreciation for chocolate’s rich history.

- Early Machinery Innovations

Let’s be real—before the 1800s, making chocolate was basically an artisanal hustle. People were just grinding stuff by hand, hoping for the best, probably making a mess. Then, things got interesting. Coenraad Johannes van Houten, shows up in 1828 with the cocoa press. Game-changer.

But hold up, things get even wilder in the 1870s. Then along comes Rodolphe Lindt—you know, the dude behind those fancy-ass Swiss chocolates your mom pretends are only for guests. He whips up this thing called the conching machine, and bam, chocolate goes from sandpaper vibes to pure velvet goodness. Seriously, it’s like the moment when Clark Kent rips open his shirt: suddenly, chocolate’s got superpowers. Not only did these gadgets crank out more chocolate, they seriously upgraded the whole chocolate game. And, honestly? That’s how we got the glorious chocolate bars we shamelessly inhale today.

The Industrial Revolution’s Impact

The Industrial Revolution? Total game-changer for evolution of chocolate-making machines, no exaggeration. Before all those fancy machines and steam-powered contraptions rolled in, making chocolate was basically a workout. You wanted a chocolate bar?.

Suddenly, chocolate wasn’t just for the rich folks in velvet coats. Everyone started getting a taste, and let’s be real, the variety exploded. You want creamy? Crunchy? Something with a weird filling? Gotta hand it to the Industrial Revolution, right? Seriously, if those folks hadn’t cranked up the tech game, we’d all be gnawing on the same dull slab of chocolate. Talk about a snoozefest.

- Mechanization of Chocolate Production

After the Industrial Revolution barged in and shook things up, chocolate making basically got a turbo boost. Suddenly, machines were doing all the heavy lifting—grinding beans, mixing up the chocolate—stuff chocolatiers used to spend ages doing by hand. Less sweat, more sweet. The big win? Chocolate started tasting the same every time. No more weird surprises in your candy bar. People finally knew what they were biting into, and honestly, who doesn’t want reliable chocolate?

- Introduction of the Conching Process

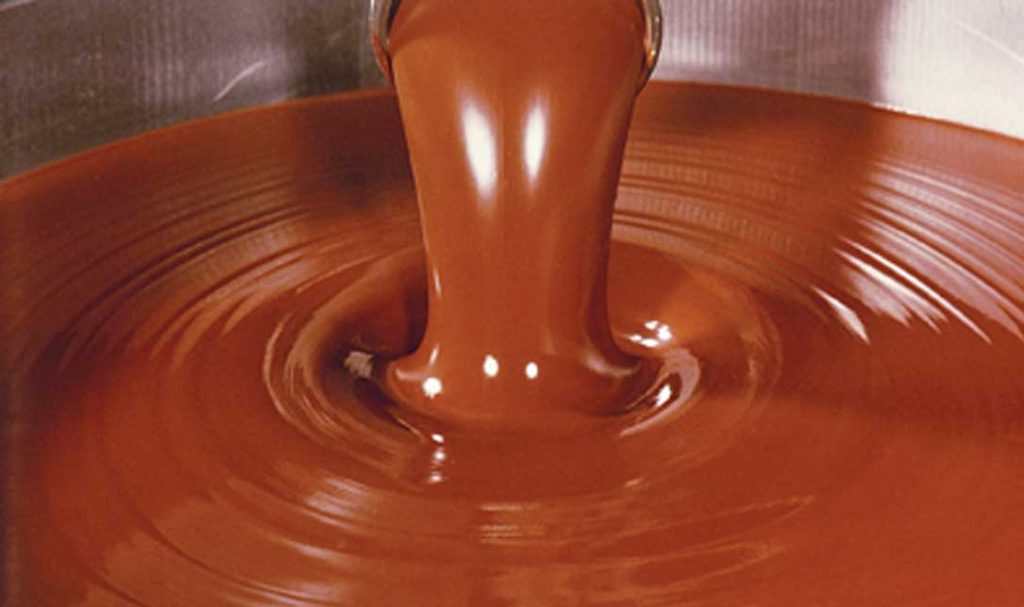

When people figured out how to conch chocolate, it basically changed the game. We’re talking about a whole new level of creamy, melt-in-your-mouth goodness. The process? Honestly, it’s not like you need a PhD to figure it out, but there’s something almost wizard-level about it—just a bunch of stirring, letting the air work its magic, and basically beating that chocolate into submission until it’s crazy smooth and bursting with flavors you didn’t even know chocolate could have. Wild, right? This whole thing kicked off in the late 1800s, and chocolate’s been living its best life ever since.

Understanding the conching process is imperative for recognizing its influence on modern chocolate. The method, perfected by Rodolphe Lindt, employs a conche — a machine designed for thorough mixing and aeration. This extended mixing time allows volatile acids to evaporate, resulting in a rich, smooth, and creamy texture.

Advancements in Chocolate-Making Technology

Assuming the chocolate-making industry continues to evolve, advancements in technology have played a significant role in creating smoother, more consistent products. From the introduction of automated tempering machines to the development of sophisticated conching equipment, these innovations have transformed the chocolate-making process. They allow for increased efficiency, better quality control, and the ability to produce larger quantities while maintaining the desired flavor profiles and textures that consumers expect.

- The Role of Automation

Role of automation in chocolate-making has revolutionized the industry, minimizing manual labor and enhancing precision. Automated systems can monitor temperatures, mixing times, and ingredient ratios with a degree of accuracy that significantly reduces human error. This shift has not only optimized production workflows but has also allowed chocolatiers to focus more on creativity and innovation rather than repetitive tasks.

- Modern Machinery Features

You’ve got all this high-tech stuff—touchscreens everywhere, recipes saved right in the machine (so you never have to dig through a dusty binder again), and real-time monitoring that basically babysits your chocolate so it turns out perfect every time. Plus, they’re built tough now—like, you could probably drop a wrench on one and it wouldn’t flinch. Cleaning’s a breeze, too, which is awesome because nobody wants last week’s mess in their next batch. Food safety folks can chill out, and the whole process just runs smoother. It’s like chocolate-making on easy mode.

So yeah, these days manufacturers can actually switch things up way faster—thanks to all the fancy new machines. Wanna make dark chocolate? Flip a setting. Suddenly need to pump out some white chocolate or throw in a weird new flavor? No big deal. Plus, a lot of the gear basically cleans itself now, which is pretty wild. No more scrubbing for hours or worrying about leftover gunk messing with the next batch.

Smart Technology in Chocolate Production

After traditional chocolate-making methods paved the way, smart technology has revolutionized production processes. Modern machines utilize advanced robotics, automation, and data analytics to enhance the efficiency, consistency, and quality of chocolate products. They allow manufacturers to precisely control various parameters, reducing waste and ensuring that every batch meets high standards, ultimately leading to better product satisfaction among consumers.

- IoT and Machine Learning Applications

Once IoT and machine learning crashed the chocolate-making party, everything changed. These days, it’s machines gossiping with each other nonstop, snatching up real-time data and just, you know, changing things as they go. One second, they’re like, “Hey, this mixer’s about to lose its mind,” or they notice the cocoa beans are having an off day and just—boom—adjust everything right in the middle of production. Wild stuff, honestly. Pretty sweet, right?

- Benefits of Smart Chocolate-Making Machines

Smart chocolate machines are kind of a game-changer. They crank out chocolate faster than your grandma can say “cocoa,” and the stuff actually tastes the same every time (which is wild, right?). Plus, nobody has to babysit the machines all day, so companies save a bunch on labor and don’t have to worry about some guy accidentally dumping salt instead of sugar. The best part? These gadgets can basically think for themselves, tweaking the recipe on the fly if something’s off. And since the tech is so clever, chocolatiers can mess around with weird flavors and funky textures—so if you ever wanted wasabi-caramel truffles, well, your dreams are closer than you think.

Also, the benefits of smart chocolate-making machines extend beyond efficiency. They enhance sustainability by minimizing resource usage and waste, as smart systems can optimize energy consumption and ingredient sourcing. By harnessing data-driven insights, manufacturers can implement sustainable practices that resonate with environmentally-conscious consumers, thus driving brand loyalty and expanding market share in an evolving industry.

Sustainable Practices in Chocolate Manufacturing

A bunch of chocolate companies are actually stepping up their game. They’re not just talking the talk; they’re getting their cocoa from farms that have those legit certifications, plus they’re bringing in greener tech to clean up their act.

People care way more about where their chocolate comes from these days—nobody wants a guilty snack, right? So, brands are jumping on the sustainability train, not just to look good, but because, honestly, if they don’t, there might not even be cocoa left in a few decades

- Reducing Waste and Energy Consumption

EcoFriendly practices in chocolate manufacturing focus on minimizing waste and energy consumption throughout the production process. By utilizing energy-efficient machinery and recycling by-products, chocolate makers are able to streamline operations while decreasing their carbon footprints.

Future Trends in Chocolate-Making Machines

Chocolate-making machines are getting a serious glow-up. We’re talking robots, sensors, all that jazz—pretty wild, honestly. Companies aren’t just churning out extra chocolate—nah, they’re on a mission to make it fancier, tastier, and hey, even eco-friendly. Folks these days are hunting for wild flavors and funky textures, so you bet these machines are leveling up. Plus, there’s way less guilt about trashing the planet. It’s kind of a win-win… unless you’re a traditionalist who thinks only grandma should make chocolate by hand.

- Potential Technological Developments

AI and machine learning—yeah, those aren’t just some Silicon Valley lingo anymore. Oh, and 3D printing chocolate? That’s a real thing. Because apparently, regular chocolate bars weren’t cool enough. Plus, these techy wizards are figuring out how to nab ingredients without wrecking the planet, which, honestly, is kind of a big deal.

- Consumer Preferences Shaping the Industry

Developments in consumer preferences are significantly influencing the chocolate-making industry. As consumers become more health-conscious and environmentally aware, they increasingly seek out organic, fair-trade, and ethically sourced chocolate options. This shift encourages manufacturers to adapt their production methods, incorporate healthier ingredients, and offer transparent sourcing practices. By responding to these preferences, chocolate makers can strengthen brand loyalty while staying relevant in a competitive market.

With the demand for personalized and unique chocolate experiences on the rise, chocolate makers are increasingly focused on creating products that cater to individual tastes. They recognize the importance of transparency in ingredient sourcing and ethical practices, which are pivotal in attracting discerning customers. This awareness drives innovation and collaboration, leading to the development of healthier and more sustainable options that resonate with the values of modern consumers.

Conclusion

Chocolate-making machines have seriously leveled up. Like, we’ve gone from those old-school, hands-on methods to these wild, techy contraptions that basically do everything except eat the chocolate for you. Funny how she really goes all-in on how automation’s changed the game—stuff’s faster, smoother, and honestly, way more consistent now.